Powder Ribbon Mixer WLDH

-

Payment

-

Origin

China Mainland

-

Minimum Order

15

-

Packing

Pieces

- Contact Now Start Order

- Description

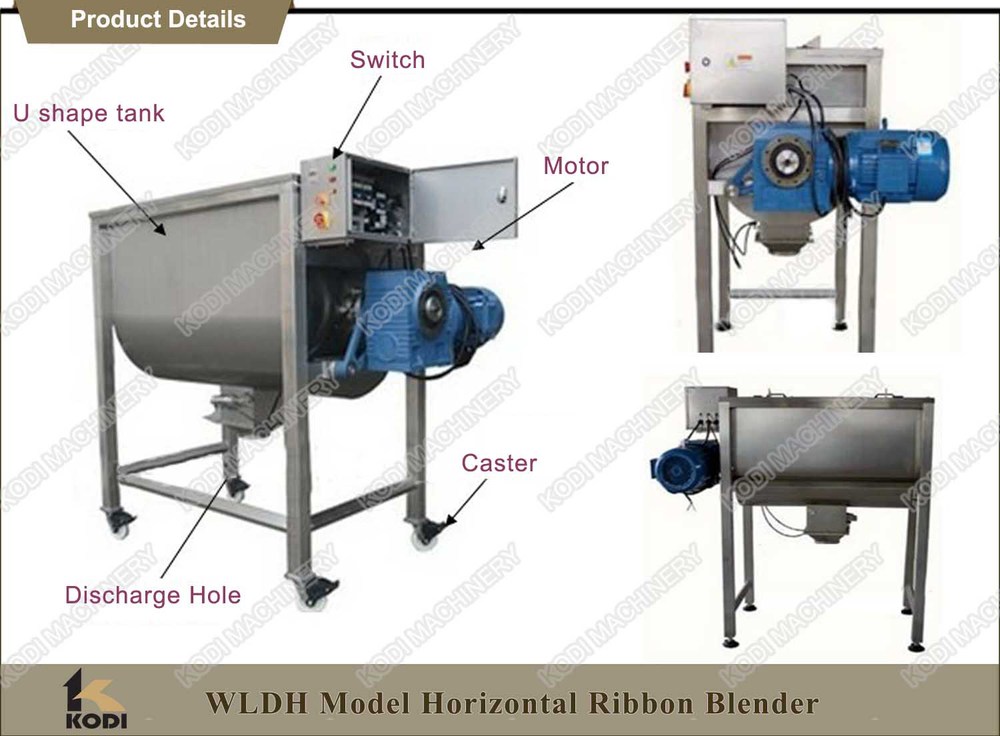

Product Detail

If you are checking powder ribbon mixer wldh price, or looking for cheap high torque powder ribbon mixer wldh, welcome to contact KODI Machinery, we are one of the leading China powder ribbon mixer wldh manufacturers.

Quick Details

Condition: New

Mixer Type: Ribbon

Product Type: powder

Application: Powder

Additional Capabilities: Ribbon Blender

Place of Origin: Jiangsu, China (Mainland)

Brand Name: KODI

Model Number: WLDH

Max. Loading Capacity: 15000L

Voltage: 220v-450v

Power(W): 3-55kw

Dimension(L*W*H): Deponds on the model

Certification: CE,ISO9001

Warranty: 1 year

After-sales Service Provided: Engineers available to service machinery overseas

Product Name: WLDH Model Horizontal Powder Ribbon Blender

Material: Stainless steel, carbon steel

Volume: 0.1-15m³

Loads coefficient: 0.4-0.8

Weight: 330-9950kg

Spare parts: supply the whole lifetime

Installation: KODI service

Energy consumption: Low

Power: 3-55kw

Cylinder shape: U shape

Packaging & Delivery

| Packaging Details: | WLDH Model Powder Ribbon Blender/ horizontal Powder ribbon mixer/ horizontal Powder spiral mixer is packing with plywood box or As customers' requirement |

|---|---|

| Delivery Detail: | 30-40 days |

WLDH Model Stainless Steel Horizontal Powder Ribbon Blender

1, Powder Ribbon Blender/ horizontal Powder ribbon mixer/ horizontal Powder spiral mixer

2, U shaping design

3, Easy operate and maintance

4, Widely application

Product Description

What is Powder

A powder is a dry, bulk solid composed of a large number of very fine particles that may flow freely when shaken or tilted. Powders are a special sub-class of granular materials, although the terms powder and granular are sometimes used to distinguish separate classes of material. In particular, powders refer to those granular materials that have the finer grain sizes, and that therefore have a greater tendency to form clumps when flowing. Granulars refers to the coarser granular materials that do not tend to form clumps except when wet.

Typically, a powder can be compacted or loosened into a vastly larger range of bulk densities than can a coarser granular material. When deposited by sprinkling, a powder may be very light and fluffy. When vibrated or compressed it may become very dense and even lose its ability to flow. The bulk density of coarse sand, on the other hand, does not vary over an appreciable range.

The clumping behavior of a powder arises because of the molecular Van der Waals force that causes individual grains to cling to one another. Actually, this force is present not just in powders, but in sand and gravel, too. However, in such coarse granular materials the weight and the inertia of the individual grains are much larger than the very weak Van der Waals forces, and therefore the tiny clinging between grains does not have a dominant effect on the bulk behavior of the material. Only when the grains are very small and lightweight does the Van der Waals force become predominant, causing the material to clump like a powder.

Description of Horizontal Powder Ribbon Blender

Powder is material composed of very fine particles that are not cemented together

Horizontal Powder ribbon mixer is a brand-new mixer. It is characterized in high efficiency, high degree of homogeneity, high load coefficient, low energy consumption, low pollution, little destruction to frangible material. It is suitable for mixing a wide range of materials such as powder-powder, power-liquid, especially for paste, thick materials.

Powder Ribbon Blender is composed of container, screw stirring paddles and transitional parts: the screw paddle are generally made into 1 layers or 3 layers, the outer screw converge is the material to the center from two sides, and the inner layer of screw conveys the material to the two sides from the center, so as to from convection mixing of powder which needs to add liquid, and paste material

Main Use and Application of Horizontal Powder Ribbon Mixer

The Horizontal ribbon mixer is generally used to mix viscous or adhesive powder material,or powder with liquid additive,or pasty material.Because it is difficult to clean viscous material,the machine is good at mixing material with large capacity and continuous demand. This machine is applied in the industry of pharmaceutical,foodstuff,chemical,pesticides,plastic,pigment and cosmetics.

Standard configuration of Powder Blender Mixer

1. Drive Unit: Cycloid reducer or gear reducer

2. Motor brand: Siemens (made in China)

3. Gear box brand: Chinese Famous brand (Huaxing)

4. Bearings: Chinese Famous brand

5. Discharging valve: pneumatic flap valve (no dead angle when mixing).

6. Main Shaft Seal

Air-purged seal and stuffing seal for powder material

Mechanical seal for liquid material

7. Voltage and Hz

380V 3Phases 50hz or in accordance with it in the using place

8. Top Cover

Could be fully open so as to clean, with safety grid and limit switch to make sure safety operation for workers

9. Normal duty type: start the mixer first and then load the material

10.Packing in pallet or wooden case

Additional configuration

1. Driven unit: Many worldwide famous brands are for option: SEW, ABB, Siemens and so on

2. Bearings: NSK/TNT and so on

3. Heating/cooling jacket

4. Spraying system

5. Heavy duty type ( loading your material into the mixer first and then start the mixer)

6. Platform: we build the platform for you or we design it and you build it locally

7. Mixing system: including packing machine, bucket elevator, Sieve, screw conveyor and so.

Customizing according to client’s specific requirement

Features of KODI Horizontal Powder Ribbon Blender

1) Stable working, noiseless, easy to disassemble;

2) Available for continuous use;

3) Energy saving, compact structure, high precision transmission;

4) Strong loading capability and easy to assemble;

5) Less influenced by particle size and density;

6) With jacket or coil to heating;

7) Dedusting system and injection system for option;

8) Star/knife-edge/butterfly types valve for option;

9) Manual or pneumatic valve discharge.

Technical Parameters of Horizontal Powder Ribbon Blender

|

Model |

All volume |

Loads coefficient |

Electrical machinery power |

Size(mm)× Max-diameter ×High |

Equipment weight (kg) |

|

WLDH-0.1 |

0.1 |

0.4-0.8 |

3 |

1190×740×770 |

330 |

|

WLDH-0.3 |

0.3 |

0.4-0.8 |

4 |

2030×630×980 |

720 |

|

WLDH-0.5 |

0.5 |

0.4-0.8 |

7.5 |

2320×730×1130 |

980 |

|

WLDH-1 |

1 |

0.4-0.8 |

11 |

2800×920×1320 |

1700 |

|

WLDH-1.5 |

1.5 |

0.4-0.8 |

11 |

3180×1020×1550 |

1800 |

|

WLDH-2 |

2 |

0.4-0.8 |

15 |

3310×1120×1640 |

2100 |

|

WLDH-3 |

3 |

0.4-0.8 |

18.5 |

3750×1290×1820 |

3000 |

|

WLDH-4 |

4 |

0.4-0.8 |

22 |

4220×1400×1990 |

3980 |

|

WLDH-5 |

5 |

0.4-0.8 |

22 |

4220×1500×2100 |

4620 |

|

WLDH-6 |

6 |

0.4-0.8 |

30 |

4700×1610×2260 |

6180 |

|

WLDH-8 |

8 |

0.4-0.8 |

37 |

4420×2150×2470 |

8200 |

|

WLDH-10 |

10 |

0.4-0.8 |

45 |

5520×2960×2720 |

8920 |

|

WLDH-12 |

12 |

0.4-0.8 |

45 |

5720×3010×2840 |

9520 |

|

WLDH-15 |

15 |

0.4-0.8 |

55 |

5840×3540×2940 |

9950 |

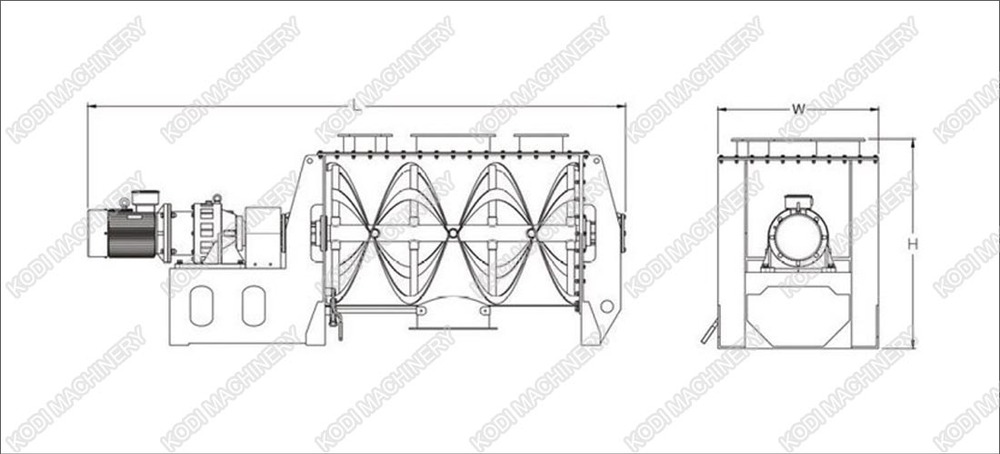

Drawings of Horizontal Powder Spiral Mixer

Packaging & Shipping

- Hide Gelatin Line KDSCX 15 Pieces / (Min. Order)

- Milk Fermentation Tank FJ 15 Pieces / (Min. Order)

- Ex Proof Glass Reactor PGR 15 Pieces / (Min. Order)

- Dust Collecting Superfine Pulverizer WFJ 15 Pieces / (Min. Order)

- Monosodium Glutamate Horizontal XF 15 Pieces / (Min. Order)

- Stevia Vacuum Dryer SZG 15 Pieces / (Min. Order)

- Blood Spray Dryer Lpg 15 Pieces / (Min. Order)

- Laboratory Spray Dryer LPG-5 15 Pieces / (Min. Order)

- Lab Spray Dryer LPG-5 15 Pieces / (Min. Order)

Favorites

Favorites